Four Board Stool

Adapting to material and resource limitations; optimizing output under strict project constraints.

A challenge in high-tolerance woodworking and DFA.

This project was a vessel for an important lesson in the concept of Designing For Assembly.

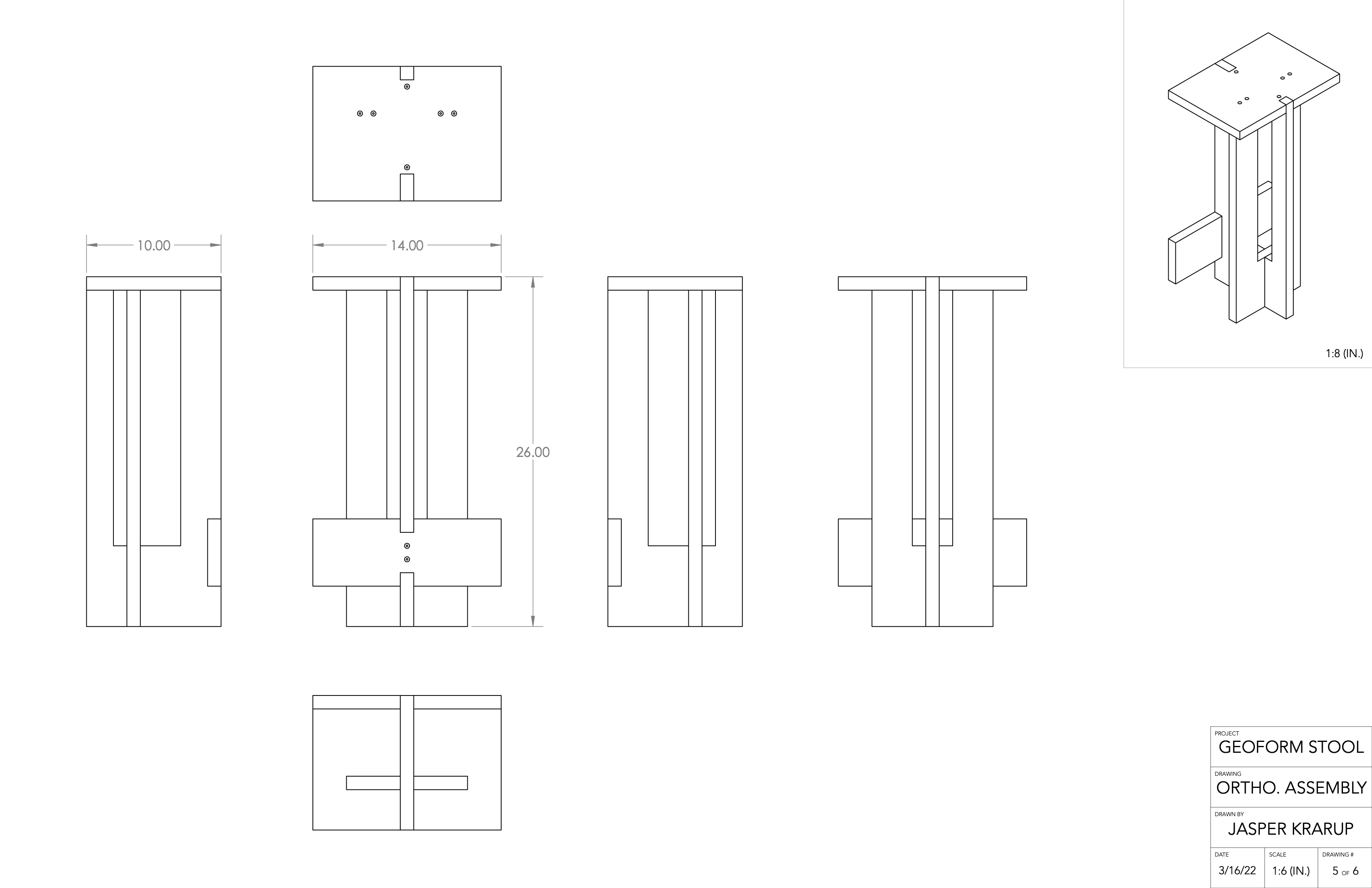

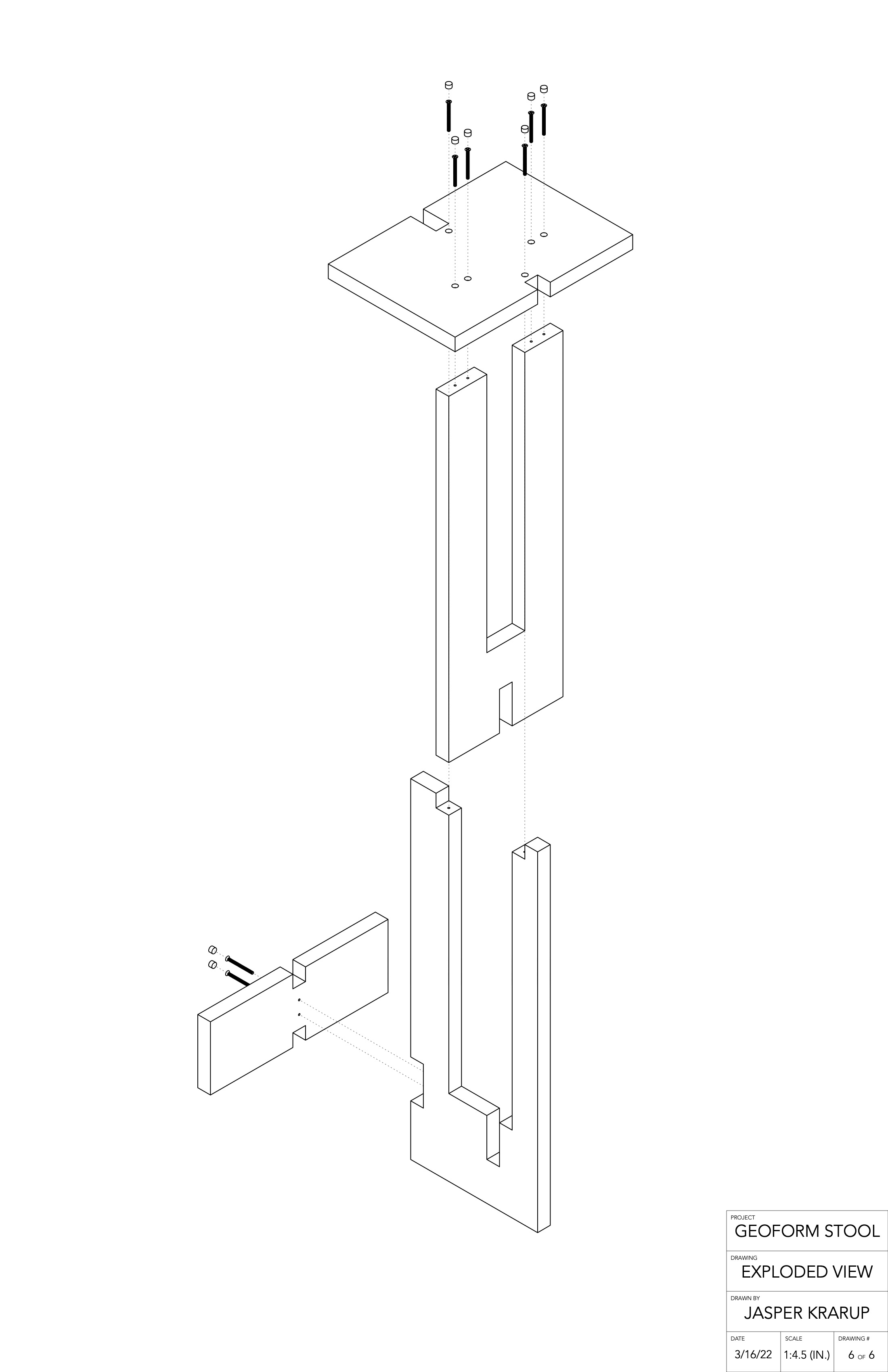

The first stage was the designing stage, where we conceptualized, drafted, and scale modeled our stools. Once our design was final, we used SolidWorks to create 3D models and blueprints, orthographics, and exploded view files. This was a crucial step that would largely determine success in the next step.

The second stage was fabrication. We traded plans with our classmates, each crafting someone else’s stool, while someone else made ours.

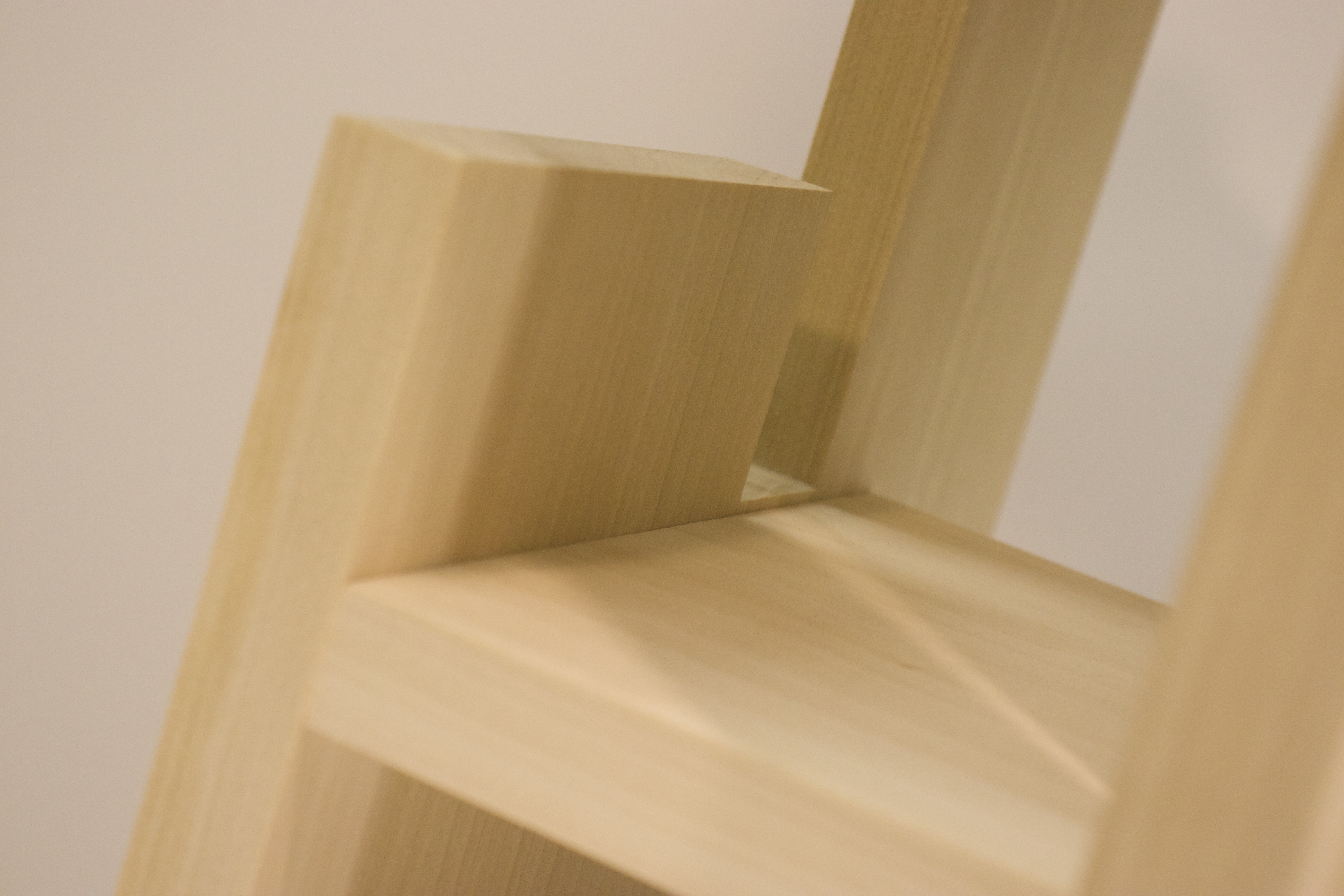

Stool: fabricated by me, designed by Jiyeon Chun.

Files: fabricated by Julia LePoer, designed by me.

Bespoke Design • Physical Fabrication • Design for Assembly

Poplar • Wood Screws • Wood Glue

SolidWorks • Woodshop Machinery

Poplar • Wood Screws • Wood Glue

SolidWorks • Woodshop Machinery